Rigged for success

The rig was chartered from the Rosshavet shipping company in Sandefjord south of Oslo via the Ross Rig A/S subsidiary. After completing its service with Statoil, it was renamed Ocean Nomad and continued drilling worldwide. In 2020, however, it was laid up in Scotland while waiting to be scrapped.[REMOVE]Fotnote: https://www.bbc.co.uk/news/extra/ao726ind7u/shipbreaking

Back in 1973-74, the market for drilling rigs on the Norwegian continental shelf (NCS) was tight. The oil crisis and high crude prices, combined with exploration success on Ekofisk, Frigg and later Statfjord, meant many companies wanted to explore in both British and Norwegian sectors of the North Sea. Statoil was on the offensive and had created its own exploration organisation as well as submitting a plan for dealing with the “key blocks”, where it expected much activity. As usual, CEO Arve Johnsen took a bold approach and maintained that securing a long-term rig charter for three-five years would be advantageous. Others believed that this might quickly become expensive if the unit had to lie idle because the number of drilling targets was insufficient.[REMOVE]Fotnote: Johnsen, Arve, 1988, Utfordringen: 131.

New and Norwegian

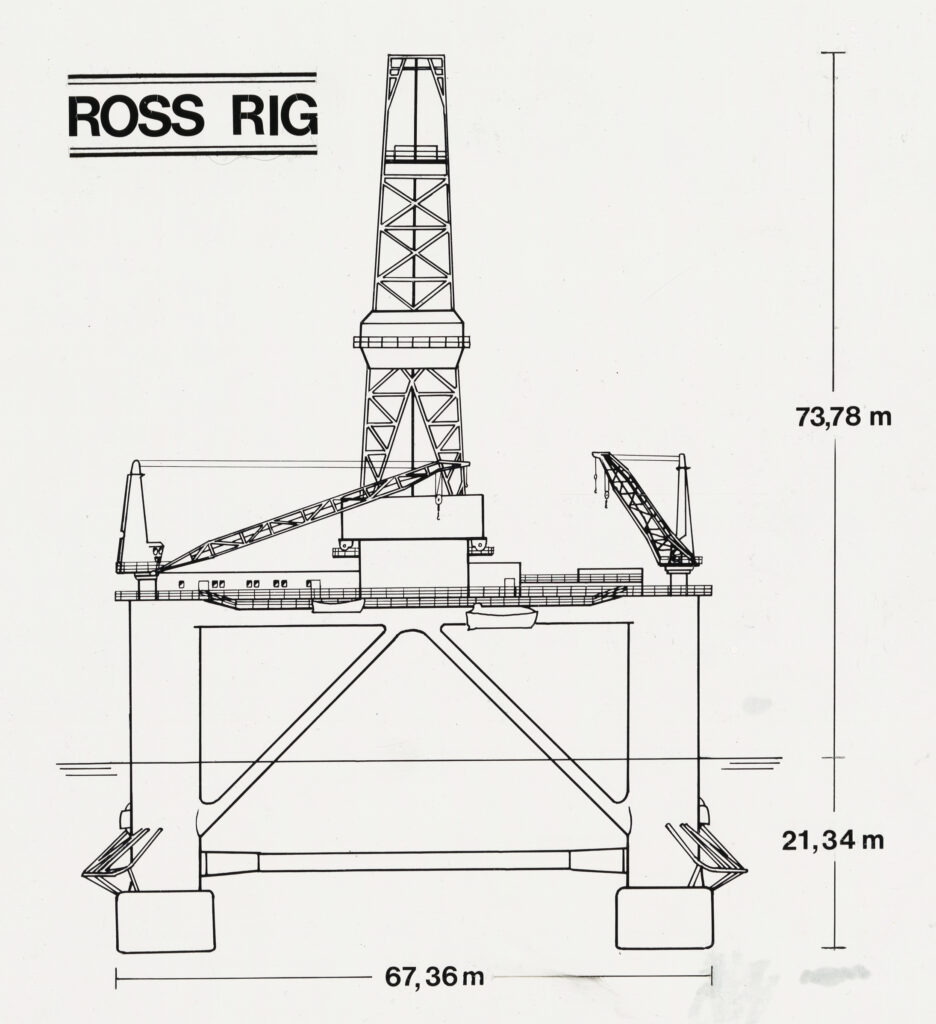

The choice fell on a new Norwegian rig rather than an older vessel. Ross Rig had been built in Brevik and outfitted in Sandefjord. Several members of Statoil’s drilling team monitored its construction, and Johnsen’s concerns about progress in building up and training an in-house team were largely met with a laconic “It’s OK” from drilling and production head Eugene Muehlberger. The rig was an Aker H-3 type designed for North Sea conditions, which meant it would be better able to handle rough weather than existing units. Deep Sea Driller, the first Aker H-3 to be completed, was reportedly more than twice as efficient as other semi-submersibles.[REMOVE]Fotnote: Blikå, T, 1989, Aker Verdal 20 år: 26-27.

Built over two years, Ross Rig was equipped with the most modern equipment available so that it could drill in waters down to 300-350 metres and perhaps even deeper.[REMOVE]Fotnote: Sandefjords Blad, 20 June 1975.

Statoil recruited five people in 1975 for immediate dispatch to the USA for training as tool pushers, so that the company would be equipped to operate the rig itself.[REMOVE]Fotnote: Status, no 8, vol 2, 1975.

The naming ceremony for the semi-submersible, which evoked associations with the Rosshavet company and its background in Antarctic whaling, took place on 19 June 1975. Just under a month later, Ross Rig was on location in block 15/12, and the very first well drilled by a Norwegian operator on the NCS was spudded (started) on 7 July. Esso was Statoil’s technical assistant and “driving instructor” for the operation. The well target had been selected on the basis of a discovery on the UK side of the boundary, just five kilometres away, and the hope was for oil in Palaeocene sandstone. While drilling progressed without any drama to a depth of 3 269 metres, however, only traces of hydrocarbons were encountered.[REMOVE]Fotnote: Completion report, well 15/12-1, Norwegian Petroleum Directorate, https://www.npd.no/en/.

After yet another dry well in block 15/12, with absolutely no sign of petroleum on that occasion, the rig was sublet to Esso, Conoco and Amoco for the following year. Achieving operator status is a necessary milestone for a company which wants be vertically integrated – covering the whole span of operations – in the oil sector. Esso’s role as technical assistant made an important contribution in that respect.[REMOVE]Fotnote: Status, no 6, vol 2, 1982.

First find

After four wells by the rig for other operators, the time had come for Statoil to stand on its own two feet and drill the first well completely on its own account. This was in block 1/9 close to Ekofisk, on a structure named Tommeliten Alpha. The main target was oil in rocks of the same age and type as the Ekofisk reservoir. Spudded in the autumn of 1976 and completed in February 1977, this well was reported to have progressed “without serious problems or accidents of a serious nature”.

The completion report from the well nevertheless talks both of a loss of drilling fluid to the formation and a kick, where formation fluid entered the well. Such incidents can be dramatic. Furthermore, mooring chains on the rig parted three times, which ultimately prompted a decision to plug the well temporarily in order to replace all the chains with ones inspected and approved by classification society Det norske Veritas.[REMOVE]Fotnote: Completion report, well 1/9-1, npd.no.

On 20 November 1976, after drilling for 37 days, chalk cuttings turned up from 3 045 metres beneath the seabed which shone under fluorescent light – an indication of the presence of hydrocarbons. Statoil had made its first find as operator.

Almost 200 metres of cores were retrieved, and the discovery formation was thoroughly tested to investigate its production properties. The conclusion was that this was a gas/condensate discovery which needed further appraisal. Such clarifications were not always obtained quickly, as the history of Tommeliten Alpha emphatically illustrates. Three further wells were eventually drilled to evaluate and delineate the discovery – the most recent in 2003. But it is still under assessment and “development solutions are now being studied, all with a tie-back to the Ekofisk complex”.[REMOVE]Fotnote: https://factpages.npd.no/en/discovery/pageview/all/43850

Unusually high rate

Ross Rig drilled a total of 24 wells with Statoil as operator, and the original five-year charter was extended by two years until 1982. Drilling operations were run from the Dusavik base outside Stavanger until 1980, when an office for such management was also established at Coast Center Base near Bergen. Discoveries were made in 17 of the wells, which included both wildcats (first on a prospect) and appraisals. That represents an unusually high finding rate. This was not only down to good luck or the rig’s inherent qualities, but also reflected the range of good drilling opportunities available to Statoil. Its geologists and geophysicists were also good at picking the right targets.

The following fields were discovered with Ross Rig.

| Fields | Year |

| 1/9-1 Tommeliten Alpha | 1976 |

| 1/9-4 Tommeliten Gamma | 1978 |

| 34/10-1 Gullfaks | 1978 |

| 34/10-2 Gullfaks South | 1978 |

| 7120/8-1 Askeladd (part of the Snøhvit field) | 1981 |

| 15/9-15 Gungne | 1982 |

Of these, it is worth highlighting Gullfaks, which ranks as the first field to be discovered, developed and produced by a Norwegian operator.

First Barents Sea flare

Towards the end of its Statoil charter, Ross Rig made an important discovery in block 7120/8, part of the Hammerfest Basin region in Norway’s Barents Sea sector. Two wells in 1980 with dead oil – just traces of hydrocarbons – were promising, but nothing to make a fuss about even though “everyone” thought a massive discovery had been made.[REMOVE]Fotnote: Alf R Jacobsen, 2010, Snøhvit. Historien om olje og gass i Barentshavet. Both Norsk Hydro and Statoil were back in 1981 with a rig each, which had to be on location simultaneously for precautionary reasons. Although Hydro admittedly made the first discovery with its 7120/12-1 well nearby, it was Ross Rig which first ignited a test flare in the Barents Sea. This discovery was named Askeladd and aroused huge expectations in northern Norway. But it took until 2007 before production began as part of the Snøhvit development.

Jan Martinussen, who was master on Ross Rig throughout the seven years it worked for Statoil, explained: “One reason for the rig’s success in exploration drilling could have been that we had a stable crew and good environment on board throughout”. Many people considered it a big advantage that owner Rosshavet wanted to employ Norwegian crew, and Martinussen reports that lack of language problems and little personnel turnover helped to create an experienced workforce.

At a time and in an environment which could be pretty rough and ready, Ross Rig stood out a bit – both with a sign proclaiming it to be the “home of the good guys” and the presence of Anne Sandell – one of the first female medics on the NCS.[REMOVE]Fotnote: Status, no 6, vol 2, 1982.

Over to Odeco

After ending its charter with Statoil, Ross Rig spent 18 months laid up in Sandefjord before being acquired by America’s Odeco and renamed Ocean Nomad. In keeping with its new name, it subsequently lived a roaming life. That included drilling in the UK sector, off west Africa and off Latvia. The rig was ultimately sold to Global Marketing Systems (GMS), described as a “cash buyer of ships for recycling”, but is being retained in Scotland by the British government because of fears that it will up on a beach in India or Bangladesh for irresponsible and environmentally unacceptable scrapping.[REMOVE]Fotnote: https://www.bbc.co.uk/news/extra/ao726ind7u/shipbreaking.

Ross Rig 2

Whether good experience with the rig or its self-explanatory name was the reason is not known, but Rosshavet named another new drilling unit Ross Rig in 1986. Built this time in Japan, it also had a good finding rate. The rig later also changed its name to Transocean Arctic, and is drilling today (2020) on the NCS. But that is another story.