Northward bound – with high hopes

Various factors meant that opening the NCS above the 62nd parallel – the northern limit to the North Sea – had already been a lengthy journey. The road to success took even longer.[REMOVE]Fotnote: Rommetveit, Hilmar, “Oljeleting nord for 62. breddegrad”, Norsk Oljemuseums årbok, 2014.

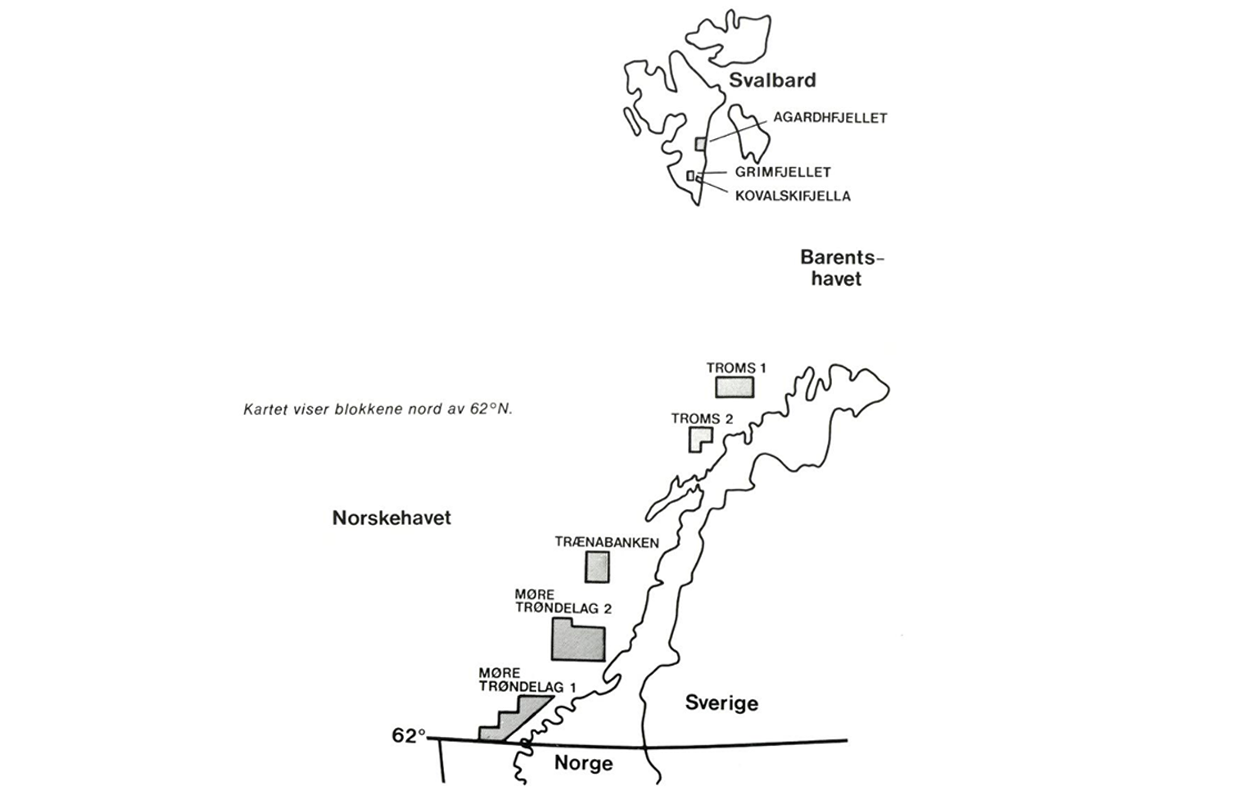

Saga Petroleum was the only operator initially in the Norwegian Sea, and made the Midgard discovery with well 6507/11-1 in 1981. This eventually became part of the Åsgard development. Further north, Statoil and Norsk Hydro competed to be first off the mark in the Barents Sea. Hydro won by spudding (starting) the first wildcat – 7120/12-1 – on 1 June 1980. Statoil was not far behind, though, and began drilling two weeks later. These initial wells were located in the Hammerfest Basin, about 150 kilometres north-west of Hammerfest itself, and aroused great expectations of substantial discoveries.

Dead oil

If a reservoir once contained oil which has since been displaced by water, residues remain attached to the sand grains. This oil cannot easily be washed out – it is immobile or dead. The water, on the other hand, can flow out of the formation. Such residual crude, which is stuck in the reservoir, will accompany cores to the surface and can easily give the false impression that recoverable oil exists in the subsurface.

Statoil’s first two Barents Sea wells – 7919/12-1 and 7119/12-2 – both yielded traces of oil in Jurassic rocks of the same age as most of the reservoirs in the North Sea. Since the cores arrived on deck full of oil, the initial reports and perceptions were that substantial discoveries had been made – perhaps bigger than Statfjord. It was a thankless task for a petroleum engineer to gather data with instruments lowered into the well (known as logging), since the results were both clear and negative. The oil was residual and non-recoverable.

To convince the most indomitable optimists, a production test was conducted. This yielded 33 barrels of highly saline formation water, which confirmed the petroleum engineer’s interpretation. Both wells were classified as “traces of hydrocarbons” – or “shows”, in oil jargon – and the disappointment was naturally great.

The exploration manager at Statoil’s Harstad office in northern Norway admitted: “We were 20 million years too late … it’s fairly clear there’s been oil and gas in this area, but faulting has caused the hydrocarbons to leak out.”[REMOVE]Fotnote: Jacobsen, Alf R, 2010, Snøhvit. Historien om olje og gass i Barentshavet, Statoil.

Third time lucky

But never give up, they say. Ross Rig was moved about 15 kilometres to the north-east, into block 7120/8, where the drama was once again played out. The Alpha structure there was estimated to hold perhaps one-three billion barrels of oil. When the drill bit reached the reservoir 2 171 metres beneath sea level, however, no unrestrained celebrations broke out as they had on Statfjord.

This well initially looked like being another disappointment, since recirculated mud and drill cuttings reaching the surface provided no visible traces of hydrocarbons. However, despair changed to relief when logging showed high electrical resistance in the reservoir. That would not have been the case if it contained only water.

One explanation for the lack of hydrocarbons on deck was the high density of the mud in the well, which pushed the oil and gas back into the formation during drilling and recirculation. But it transpired that the reservoir was full of gas. Askeladd had been discovered, marking the start of a long march towards ultimate development.

Three weeks after the logging, gas burning from the rig’s flare booms provided visible evidence that petroleum could be found beneath the seabed in the Barents Sea as well. Both the mood and the weather were such that both booms were ignited in honour of the photographer, although this was strictly not permitted.

How big?

The first appraisal well on the discovery, drilled on the southern part of the structure in April-June 1982, yielded a positive result. But planning a second appraisal met much opposition from licence partners Esso, Phillips Petroleum and Elf Aquitaine, which wanted to explore other structures which could add to commercialisation of the area. However, Statoil’s Tor-Ivar Pedersen succeeded, as chair of the licence’s management committee, in convincing Elf of the need to delineate the actual discovery they had. This well was drilled from West Vanguard in April-May 1983 and, although the result was disappointing because hydrocarbons were not encountered, it provided important data on Askeladd.

Henrik Ager-Hanssen, Statoil’s deputy CEO, announced at the 1982 ONS oil show in Stavanger that “small is beautiful”. He thereby maintained that Askeladd’s 100-150 billion cubic metres of gas were enough to justify a pipeline to land and the export of liquefied natural gas (LNG) by tanker.[REMOVE]Fotnote: Stavanger Aftenblad, 26 August 1982. He was ultimately to be proved right – but only after 25 years, so he had plenty of time to reflect over whether he had been a bit too outspoken a bit too early.

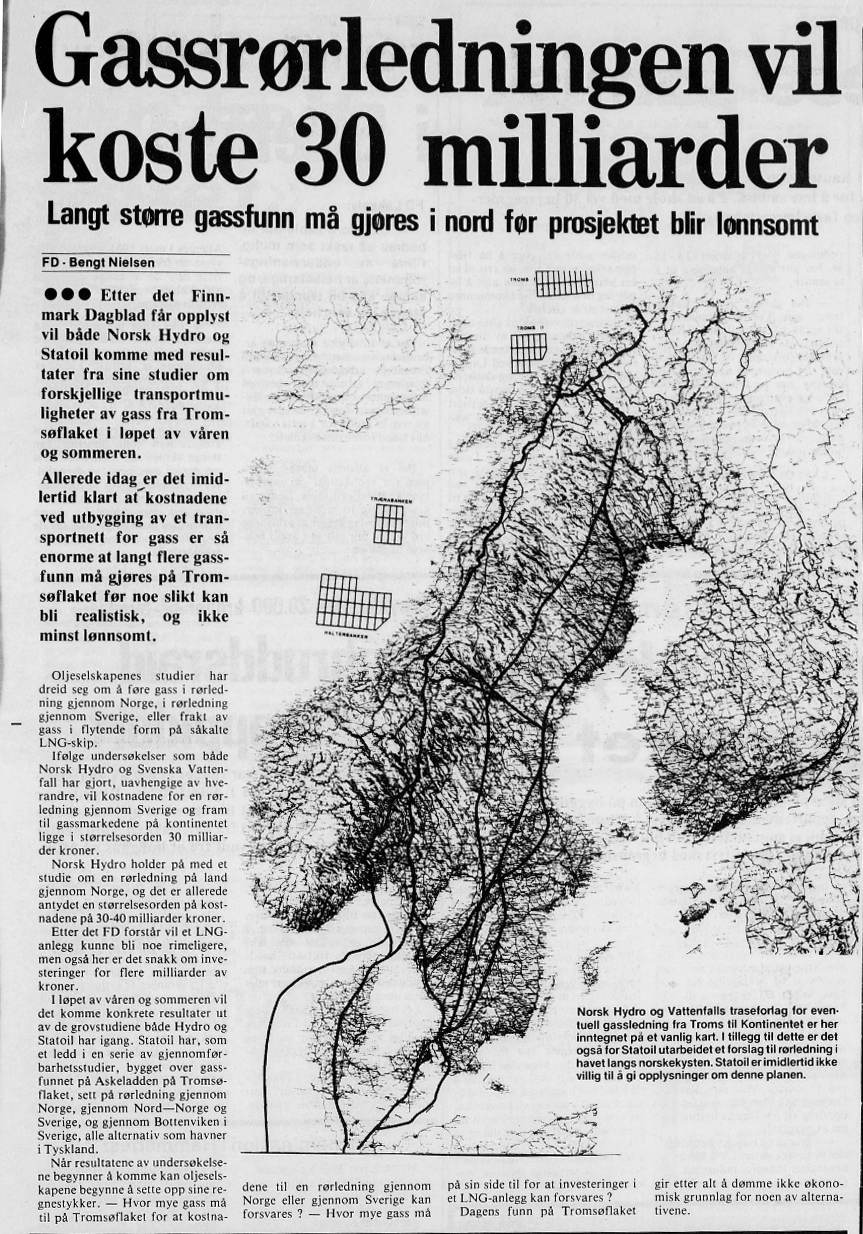

Although more gas was found in Askeladd West (1982), Askeladd Central (1983) and Albatross (1984), and both gas and oil in Snøhvit (1984), the quantities involved were not huge and developing them was not a matter of course. A long series of upturns and downturns, hopes, accusations, broken promises and political clashes led eventually to production from the area starting in 2007. During that period, development concepts under consideration included solutions similar to Troll with its concrete platform, and pipeline transport to Europe both along the seabed and across Norway and/or Sweden.[REMOVE]Fotnote: Jacobsen, Alf R, op.cit.

The ultimate answer became Ager-Hanssen’s LNG solution, which involves liquefying the gas on land and shipping it away in special carriers – particularly to Cove Point in the USA. This Hammerfest LNG plant became the world’s northernmost – and Europe’s first – gas liquefaction facility, and utilised innovative technology developed in part with Germany’s Linde.

But the development was not without its problems and faced delays and cost overruns. Indeed, the project was initially considered to be only marginally profitable. The licensees decided in the summer of 2001 that they would not go ahead without a clarification of key tax issues. Once that had been secured, a plan for development and operation was submitted to the government.

Snøhvit was the first of the discoveries to be brought on stream, and plans called for Askeladd to follow in 2020. However, this had to be delayed because of a fire at Hammerfest LNG that autumn.

Fits and starts

Exploration continued in the Barents Sea by fits and starts from the 1980s, and various developments have been purged. Snøhvit and Goliat are on stream, and will soon be followed by Johan Castberg and Wisting. However, these waters have come nowhere near the density of resources found in Norway’s North Sea sector. Recent licensing rounds have shown that interest in exploring the Barents Sea is declining.[REMOVE]Fotnote: Lindberg, Björn, 2019, “Den som leter”, Norsk Oljemuseums årbok.

Although the Norwegian Petroleum Directorate believes substantial quantities of oil and gas may lie in the unopened Barents Sea North area, this part of the NCS is unlikely ever to be a new North Sea.

arrow_backEntry to ChinaNorway’s most profitable inventionarrow_forward