Statoil’s first discovery – Tommeliten Alpha 1/9-1

That followed a couple of wells which Statoil had tackled with Esso as its technical assistant and “driving instructor”. In the autumn of 1976, it took over Ross Rig from Amoco in block 2/8 on the Norwegian continental shelf (NCS). This unit was then moved just under 30 kilometres to block 1/9, 285 kilometres south-west of the port of Egersund and almost midway between Norway, Denmark and the UK.

Once the rig was in place, the mooring line for anchor 1 was passed to the Ibis One anchorhandling vessel and the hook dropped. While preparations were being made to set anchors 1 and 7 against wind and current, however, the wind suddenly shifted. A rig measuring 108 by 67 metres naturally presents a substantial surface area, and Ross Rig was blown 350 metres west of the desired location – a fairly substantial deviation. This could be offset to some extent by hauling in on the mooring lines, and the rig was finally positioned in 78 metres of water just 70 metres from the site originally planned. After 36 hours and 45 minutes, including 16 hours of waiting on weather, Ross Rig was ready to drill Statoil’s first well for its own account.

Drilling in the name of…

Ranked as the 154th exploration well on the NCS, the operation was conducted on behalf of the Statoil/Phillips group, which also included Phillips Petroleum, Fina and Norsk Agip. Discoveries made off Norway until then were concentrated around the Ekofisk, Frigg and Statfjord finds, and the third licensing round had yet to be announced. The drilling target for 9/1-1 was a salt pillar, with petroleum being primarily sought in Danian (Palaeocene) and Cretaceous rocks dating from about 66 million years ago. This play (model) had been proven in Ekofisk about 20 kilometres away, so the prospects of finding something were good. A plan also existed to drill down to even older Jurassic and Triassic rocks, but that did not prove possible with this well. In exact terms, it was placed on seismic line 404-403 and shot point number 548.

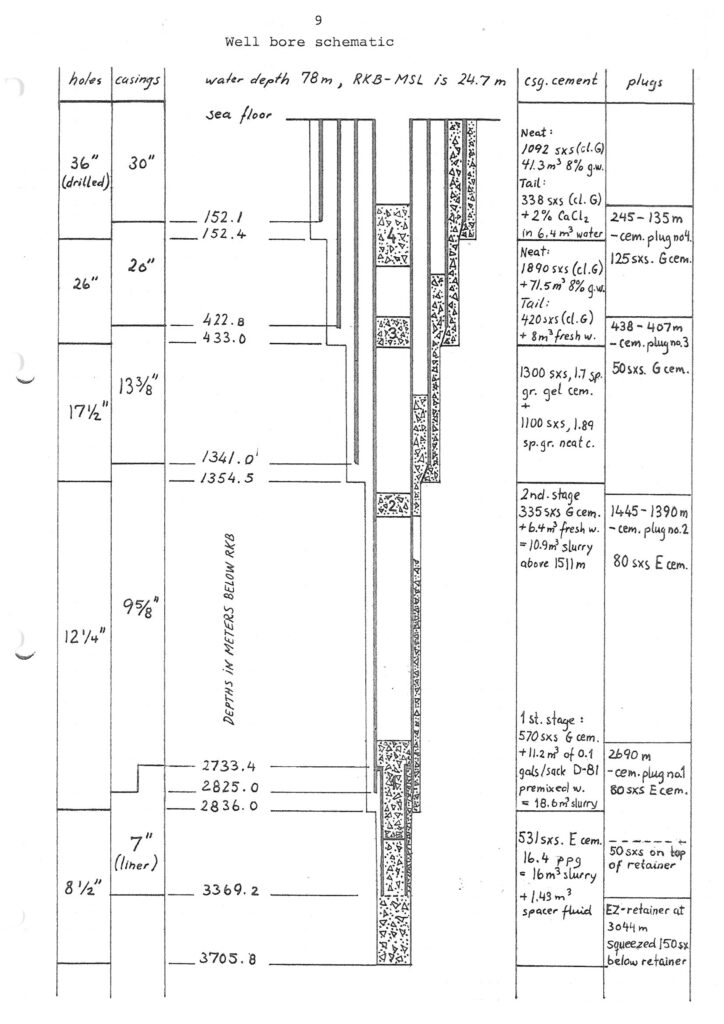

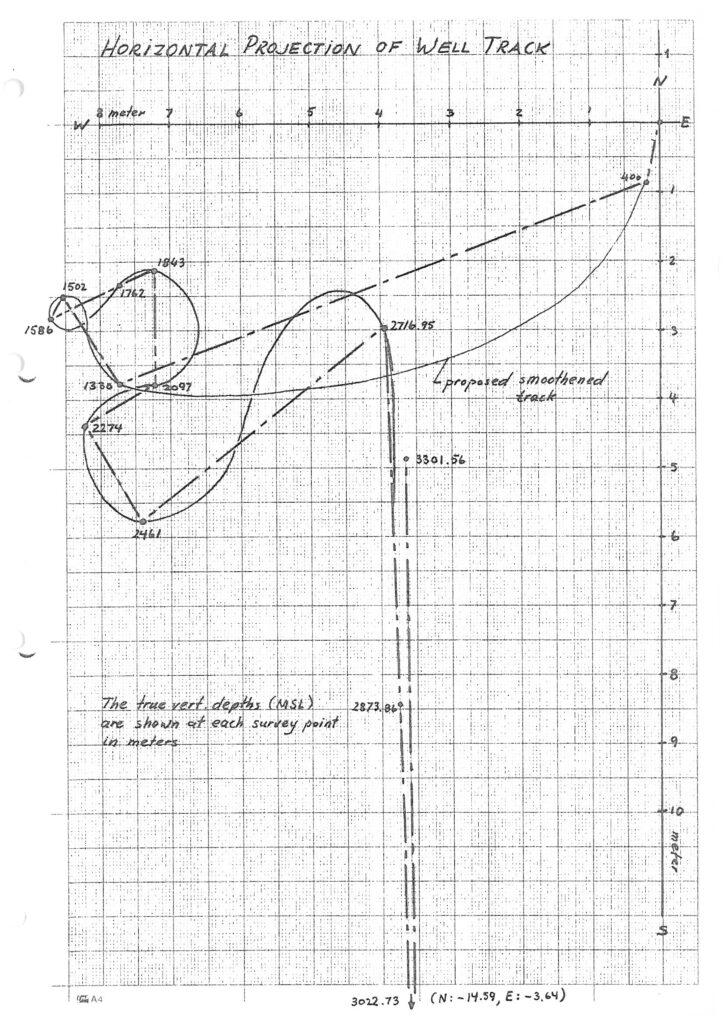

The descent to the target progressed more or less without surprises or difficulties. A 36-inch bit was used for the first 150 metres, followed by 26-, 17½- 12¼- and 8½-inch sizes. The last of these was set to penetrate the expected reservoir at a depth of more than 3 000 metres. A bit might be expected to sink vertically into the sub-surface, but that is not the case in practice. Hitting a big rock, for example, can push it out to one side, and the driller has to compensate. That can produce substantial deviations from the original target. See figure 3.

On 20 November 1976, after 37 days of drilling, chalk cuttings from 3 045 metres beneath the seabed lit up under fluorescent light when they reached the drill floor – a sign that hydrocarbons were present. That was sufficiently promising for the drilling supervisor to decide that the bit should be replaced with coring equipment. It took rather longer than expected to reach the reservoir, as figure 4 shows. The actual curve is flatter than originally calculated.

That this was relatively early in Norway’s oil age is reflected in part by the units used in the various reports. Some are in feet – standard American usage – and others in metres, which was the Norwegian standard.

Odour of success

Some people like the smell of service stations. Geologists Asmund Haga and Jakob Bleie presumably belonged in that category because they described the first core on deck as having “good odour”. Taken from 3 048 metres below the seabed, this rock cylinder was 9.2 metres long and comprised Danian chalk containing oil/condensate/petroleum. The second coring operation ran into problems when the mooring chain to anchor 1 parted, although these proved surmountable. But that chain was to cause fresh difficulties later. A total of 12 cores amounting to almost 200 metres were retrieved – important for detailed studies of porosity, permeability, water saturation and a number of other properties. The coring tool was then replaced with logging equipment to obtain further information about what might be hidden in the depths. Finally, the well was drilled to a total depth of 3 705.8 metres. Based on the logging results, it was decided to conduct a production test.

To say something about the production properties of the discovery, a drill stem test (DST) was conducted. This involved producing from various zones in the well to see how much petroleum flowed out. The test was carried out by cementing in a length of casing (seven inches in diameter for the 8½-inch reservoir section). After installing special testing equipment, a charge was detonated to perforate the casing at the desired interval. Oil and gas under high pressure then intrude into the test pipe and through chokes to the rig. No infrastructure was available to handle the oil and gas during the operation, so it was burnt off from a flare boom extending from the rig – a clear sign that petroleum is present. On 9/1-1, such DSTs were conducted in no less than eight different well intervals – an expensive and time-consuming operation.

During the final DST, the mooring chain parted again. It was decided to plug the well temporarily, allowing for further investigation later. But that did not happen, and permanent plugging followed 10 years later.

Checks of the mooring chains indicated that the steel had been overheated during the casting process. Once cast, the steel is supposed to be reheated to achieve the right temperature (normalisation). This had not be done correctly, leaving weaknesses. After normalisation of the chain and its recertification by Norwegian classification society Det norske Veritas, Ross Rig was ready for its next drilling target on Sleipner West further north.

Statoil’s first discovery, well 1/9-1, was named Tommeliten Alpha and estimated to contain about 5.6 million standard cubic metres (scm) of oil (about 35 million barrels) and 13.3 billion scm of gas. Status pr. 31.12.2021 was that ConocoPhillips has submitted a Plan for Development and Operation with expected start of production in 2024.

The article is based on information published in NPD’s fact pages.[REMOVE]Fotnote: https://factpages.npd.no/pbl/wellbore_documents/243_1_9_1_Completion_report_I.pdf