Tommeliten – valuable subsea experience

This field has been described as Statoil’s subsea school, and it functioned as a springboard for a continued commitment to technology in the underwater arena.[REMOVE]Fotnote: This article is based on chapter 6 of Getting Down to It. 50 Years of Subsea Success in Norway, 2019, by Kristin Øye Gjerde and Arnfinn Nergaard.

First discovery

Tommeliten Gamma, the part of the field covered by this article, lies in 75 metres of water 12 kilometres from the Edda platform in the greater Ekofisk area. The high pressure, high temperature chalk reservoir was proven in 1976 along with Alpha – the other structure in the field – and represented Statoil’s very first discoveries.

They were made in the same year that block 9/1 was awarded in Norway’s third offshore licensing round, originally to Statoil with 50 per cent, Phillips Petroleum 26 per cent, Fina 15 per cent and Agip nine per cent. These interests changed later because Phillips opted to withdraw from the subsequent development project, which was confined to Gamma.

Studies for developing Tommeliten began in 1977, with both conventional platform solutions and subsea facilities under consideration. But it was not until 1985, after a good deal of prevarication, that Tommeliten Gamma was declared commercial on the basis of a two-platform development concept.

About-face

Soon afterwards, a major about-face occurred. On 23 December 1985, Phillips announced it no longer wished to continue a project based on this solution. The cost was too high. Agip and Fina agreed. This was because oil prices had slumped dramatically on the world market, from more than USD 30 per barrel in October 1985 to less than USD 10 six months later.

Phillips nevertheless indicated that it had the capacity to handle Tommeliten gas on Edda, and that a subsea development could perhaps be considered.

Statoil seized this opportunity. Even though it was Christmas, new plans were drawn up a breakneck speed and Statoil went to Phillips as early as 2 January 1986 with a new proposal.

This called for the US company to study an upgrade of the Edda platform to accept the gas, while Statoil would work on a subsea development of Tommeliten Gamma. The licensees required these studies to be completed by 12 March. Phillips accepted this, and investigated opportunities for receiving Tommeliten gas on Edda. For its part, Statoil worked as fast as it could to present a solution based on subsea wells.

At that time, Statoil had become a firm believer in underwater technology – not least through its Gullfaks project in 1983, which incorporated such wells. Moreover, the technology had moved by 1985 from being relatively untried to becoming the basis for developments by both Elf Aquitaine and Norsk Hydro, with the former’s project on the East Frigg satellite already approaching completion. The Skuld project on remote control of subsea wells, led by Elf with Statoil as a participant, had been completed in 1984. Hydro was also in full swing with two subsea developments on Oseberg as well as its Troll-Oseberg gas injection (Togi) project.

All these efforts marked the start to a underwater revolution in offshore oil and gas production.

Nevertheless, Phillips was fundamentally sceptical about the value of a Tommeliten development, and opted to withdraw from the licence. Its 26 per cent share was split between Statoil, which got 21 per cent to reach 71 per cent, and Fina with an extra five per cent. Agip chose to stick with nine per cent. This was agreed by the licence on 11 March 1986, one day before the deadline.

To get the project approved by the authorities, Statoil cooperated closely with the Ministry of Petroleum and Energy over preparing the documentation. “We submitted a draft proposition [Bill] on 14 March and this was considered by the government a week later,” said project manager Helge Hatlestad. The Storting (parliament) approved the Tommeliten plan on 12 June 1986.

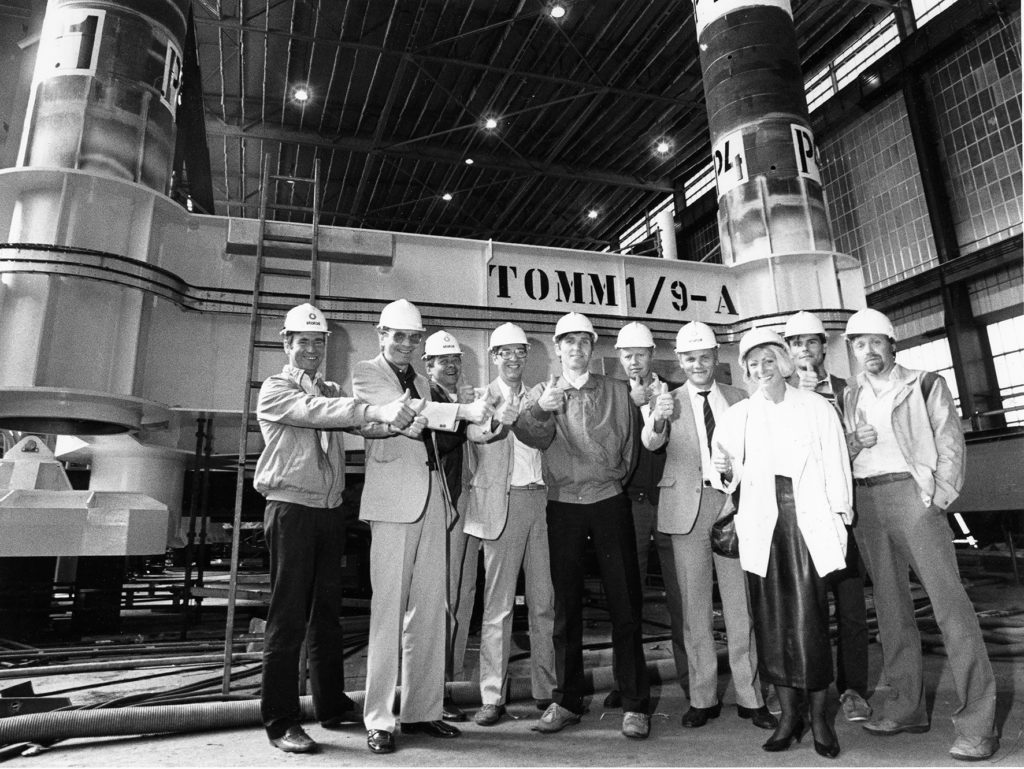

Things continued to move fast. The Storting’s standing committee on oil and energy visited Stavanger in August 1986 during the Offshore Northern Seas (ONS) exhibition, and was taken on the tour of the city’s Rosenberg Verft yard. Somebody asked what a yellow steel structure was for, and Statoil’s representatives said it was the drilling template for Tommeliten. “We’ve just discussed that!” exclaimed committee member Inger Lise Gjørv from Labour. She was astonished that it had already been built.

The template was shipped out and installed on 14 September 1986. According to Hatlestad, they had promised the drilling department to be ready on the 15th – and rang the drillers 25 minutes before midnight to say the rig could begin to move into position.[REMOVE]Fotnote: Helge Hatlestad interviewed by Trygg Methi, 4 May 2015. So drilling the production wells could begin just nine months after somebody had started to think about a subsea development.

Concept and technology

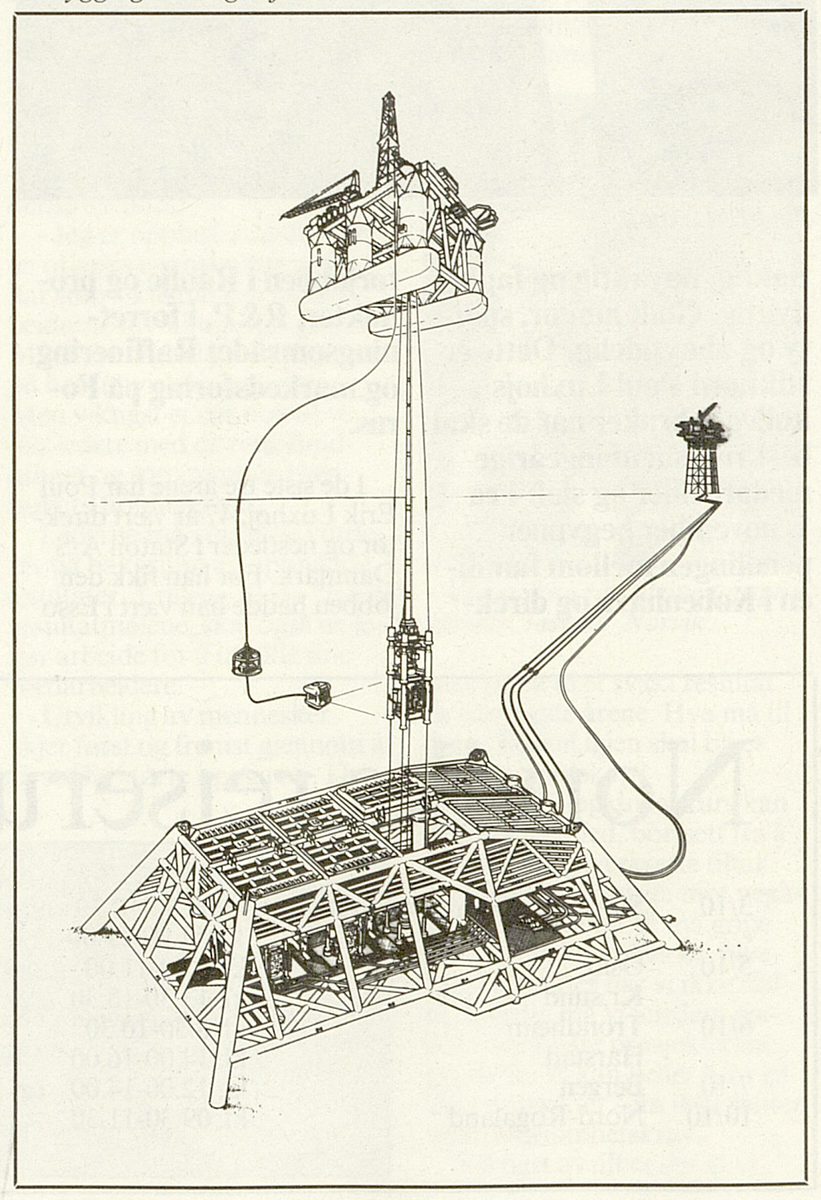

Tommeliten Gamma was developed with six wells in a seabed template, which had been split between drilling and protective structures. This subsea station was tied back to the Edda platform by two nine-inch pipelines, a six-inch test pipeline and a control and service umbilical, and operated from a separate control room.

The wellstream – in other words, gas, condensate and water emerging from the well – was piped 11 kilometres to the process plant on Edda for separation and treatment before export.

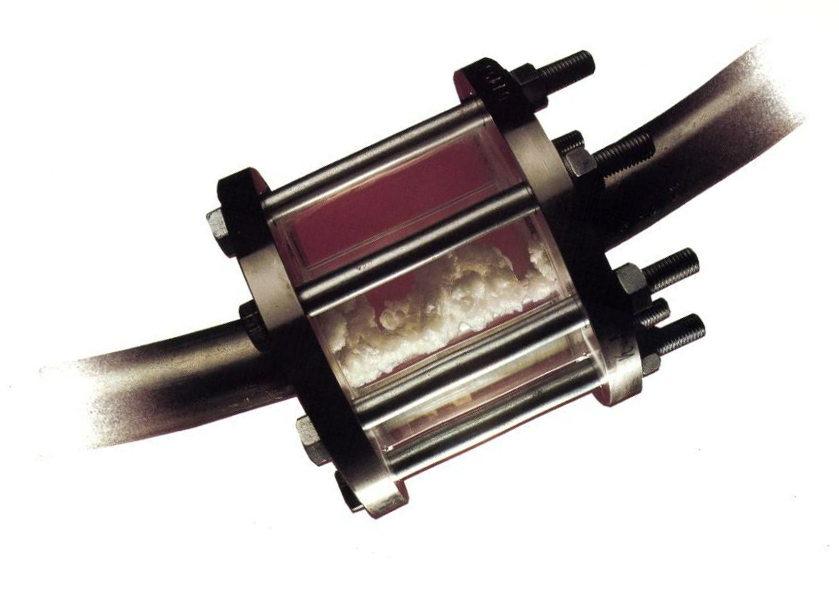

Transferring an unprocessed wellstream over such a long distance represented an innovation. So trials were staged with adding “anti-freeze” in “real-world” conditions. This was intended to avoid problems from liquid plugs and hydrates (hydrocarbon ice) forming in the pipelines. The ability to test computer models on this scale was very valuable.

While installation and connection on Tommeliten utilised diver assistance, drilling and well workovers were diverless. This offered the best overall economics, with low investment costs, a short execution time and a quick start-up.

To meet the short deadline, plans called for many development activities to be pursued in parallel. Installing the drilling template early, for example, meant this work could start as soon as possible. The protective structure – weighing 800 tonnes and measuring 42 x 26 x 12 metres – was installed much later.

Opting for diver-assisted installation and connection also saved time, since the alternative would have involved extensive design, fabrication and testing of remotely operated connection systems which the suppliers at that time had relatively limited expertise with.[REMOVE]Fotnote: Helge Hatlestad, March 1987, “Utbygging av Tommeliten feltene”, Norwegian Petroleum Society: 5

Executing the Tommeliten development so quickly attracted attention. Hatlestad commented afterwards: “We adopted a very optimistic plan and envisaged no problems. If I’d known what I was getting into and how difficult it actually was, I wouldn’t have dared. But because I didn’t know, things perhaps went well”.[REMOVE]Fotnote: Helge Hatlestad interviewed by Trygg Methi, 4 May 2015.

Although the project can be described as successful, it was certainly not without its problems along the way.

The project team comprised young people, with many who knew a bit but nobody knowing everything. It became a place to test out the unfamiliar. Men dominated, but a few women were also in the group. Solidarity was good, and the Statoil personnel became familiar with supplier personnel. That benefited later projects.[REMOVE]Fotnote: Ingrid Karstensen interviewed by Kristin Øye Gjerde and Arnfinn Nergaard, 26 April 2018.

Gas to Edda

Gas and condensate began flowing from Tommeliten to the Edda 2/7 C platform on 3 October 1988 – and it transpired that Phillips had good use for this output despite pulling out of the licence. Some was injected in the old Edda wells, substantially increasing production from the field and remaining in the reservoir for later recovery. It can therefore be said to have been produced twice.

Otherwise, the Tommeliten gas was piped directly on to Emden in Germany for distribution to consumers in continental Europe.