Statpipe – an achievement

When Johnsen was a Fulbright scholar in the USA, he learnt about the Standard Oil company and its head, John D Rockefeller, who used his pipelines to crush his competitors.[REMOVE]Fotnote: Borchgrevink, Aage Storm, 2019, Giganten: 40. So he was aware of the strategic importance of transport systems long before becoming CEO of Statoil in 1972. That underpinned the pressure he put on Phillips Petroleum in 1973-74 over control of the Norpipe pipelines from Ekofisk. Similarly, Statoil pushed hard to secure an oil and/or gas pipeline from Norway’s share of Statfjord to the Norwegian mainland.

One for oil was not laid because the Storting (parliament) decided in June 1976 that Statfjord crude would be loaded directly into shuttle tankers. But a gas link was still possible, since the Storting had also asked Statoil to conduct a two-year programme of planning and studies for a gas gathering pipeline from Statfjord to Norway.

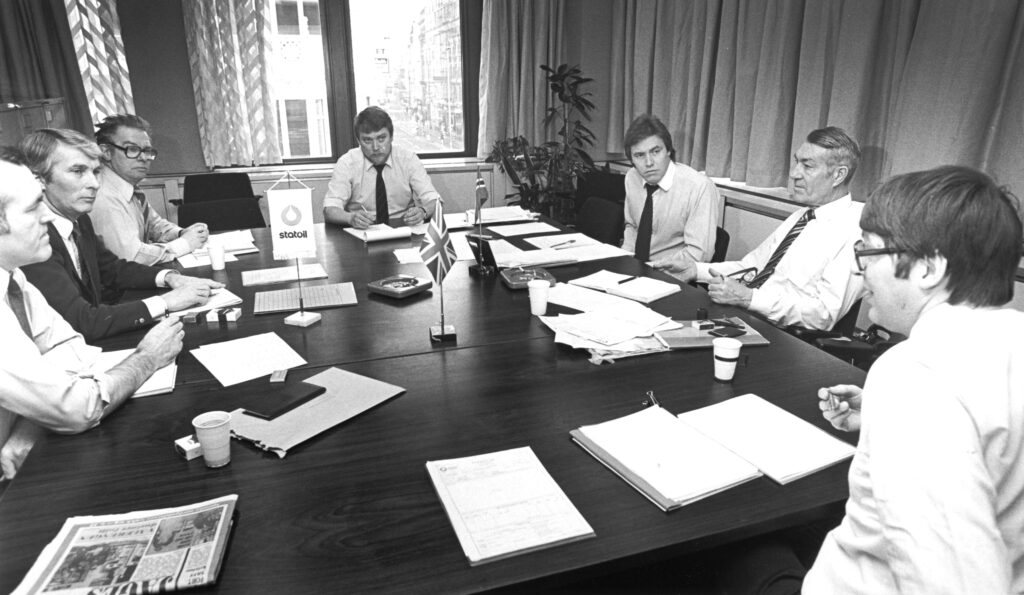

Plumber team

The company had purposefully qualified itself for such studies over a number of years, with its technical department – nicknamed the “plumbers”, a play on words in Norwegian – gaining experience from Norpipe. The latter embraced two pipelines, one for oil to Teesside in the UK and other carrying gas to Emden in West Germany. Statoil was also a partner in the Frigg gas pipelines to St Fergus.

To be equipped for big pipeline projects, the plumbers swiftly recruited metallurgists, computer specialists, engineers to calculate dimensions and economists to determine costs. By 1975, this team totalled almost 60 people, mostly engineers.

Choosing a developer

That year was when the government published a White Paper on developing and landing petroleum from Statfjord and laying a gas gathering pipeline. An important argument for building the latter was that other, smaller gas fields in the North Sea could take advantage of such a trunkline. If the government licensed blocks along the pipeline route where gas was likely to be found, landing these resources could be coordinated and their prudent utilisation ensured.

Although Statoil was the biggest licensee in Norway’s share of Statfjord, Mobil was the development and production operator. Which of them would lay and run a possible pipeline was thereby by no means given. But Statoil took action. To save time and money, the board decided on 3 February 1976 that the company would launch phase one of a pipeline study on its own account. Losing months while waiting for the White Paper would be unfortunate.[REMOVE]Fotnote: The project team was split into three main components – planning and administration, under Lars Fundingsland, terminal headed by Ove Muri and pipelaying led by Thor Haakon Helgesen, with Sverre Lund as his deputy.

Three departments worked on the project – planning and administration to draw up routines, terminal to plan the design of the process plant and prepare the selection of a site, and pipelaying. The last of these was to find solutions to the technical challenges involved.

Statoil was accordingly well prepared when the Storting approved continued work on the Statfjord transport system project, pipeline and terminal a few months later. From then on, it led the Statoil/Mobil joint venture working which worked on phase two until 1 March 1981.[REMOVE]Fotnote: Report no 90 (1975-76) to the Storting, Om utbygging og ilandføring av petroleum fra Statfjordfeltet og en samlerørledning for gass.

Planning a pioneering project

Johnsen personally followed the work of the plumbers on mapping the seabed between Statfjord and the Norwegian coast. A gas pipeline was a big investment. Construction of the pipeline itself, building the receiving terminal on land and starting up the system were expected to cost NOK 15-25 billion.[REMOVE]Fotnote: Status, no 7, 1976.

Water depths along the pipeline route varied between 150 metres at the field and more than 300 metres at the lowest point of the Norwegian Trench, which runs parallel to Norway’s coast. Video footage acquired from small submersibles allowed Johnsen himself and the project team to study what the seabed looked like. The engineers needed to determine which vessels were needed for the laying operation. Anchors to hold the laybarge in position had to be capable of coping with the soft clay covering much of the Trench seabed.

Underwater pipelines are laid over the stern of the barge, which moves forward by pulling on anchors which are constantly being repositioned well ahead by specialist ships. That made it important for the anchors to have a good grip on the seabed, and tests were needed to confirm that the clay was able to provide a sufficient hold. Securing that was easier on the western slope of the Trench and in towards land because of sand and rock deposits on the seabed. [REMOVE]Fotnote: Johnsen, Arve, 1988, Gjennombrudd og vekst: Statoil-år 1978-1987: 72-73. To satisfy fishing interests, the plans had to include trenching of the pipeline. That called in turn for the construction of a machine to cut such channels on the seabed.

Norway’s Kværner group was commissioned by Statoil to develop a trencher controlled from a surface vessel. This used the laid pipeline as a rail while cutting alongside it. The pipeline then fell into the resulting trench.[REMOVE]Fotnote: Ibid: 73.

Another difficult question was how possible pipeline repairs could be carried out in deep water – in other words, whether divers could descend in such depths to weld possible faults. This was a big challenge because saturation diving – where the diver lives in a chamber pressurised to the working depth – was still only in its infancy. The deepest dives conducted in 1973-74 has gone down to 150 metres, and descending to 300 metres was more a case of wishful thinking that reality at the time.[REMOVE]Fotnote: Gjerde, Kristin Øye and Ryggvik, Helge, 2009, On the edge, under water. Offshore diving in Norway: 175-180.

In 1976, Statoil and Mobil contributed nine people and one person respectively in a welding project run by classification society Det norske Veritas. Statoil also followed a similar Shell project for deepwater pipeline repair. [REMOVE]Fotnote: Status, no 7, 1976. But more trials were needed, and a pipelaying/repair test in 300 metres of water was therefore planned for the spring of 1978 in the Skånevik Fjord.

The plumbers had to assess the best landfall site for the pipeline, and whether a tunnel should be built to conduct it through the difficult inshore zone. Furthermore, the terminal team had to do the engineering work required for the process plant, seabed surveys and investigations for rock caverns to store oil and gas.

Based on the results of this second phase, the Storting would determine how the landing should occur. Only then could the third stage – building work on land, constructing the landfall tunnel and pipelaying from field to shore – be undertaken.[REMOVE]Fotnote: Ibid.

To Kårstø and the continent

By the time Statfjord came on stream in 1979, planning of the gas pipeline from Norway’s share had made considerable progress. While the oil was loaded into shuttle tankers, gas was initially flared. But the fifth of the 10 commandments mentioned above prohibited doing this over an extended period. Statoil accordingly started injecting gas from the Statfjord A platform back into the reservoir in June 1980. However, this also represented only a temporary solution. That was because long-term gas injection could damage the sub-surface structures. To avoid this affecting oil output, installing a pipeline to land was a matter of urgency.

Fortunately, the economic preconditions for laying a pipeline over the Trench steadily improved. Oil prices tripled after the Iranian revolution in 1979, which made a big contribution to the financial margins. Nobody doubted any longer that Statfjord would show a profit. The Statoil/Mobil group submitted an application for landing Statfjord gas to the Ministry of Petroleum and Energy in December 1980. Gas from Heimdal and Gullfaks was expected to be carried in the same system, which would be owned and run by a dedicated company with Statoil as the operator.[REMOVE]Fotnote: Stafsnes, Tor, 1984, Ilandføring av petroleum fra Statfjord: analyse av en iverksettingsprosess, Bergen: 97-99.

This application was considered by the Storting on 10 June 1981, when the final decision on where the gas should be landed in Norway was taken. As so often in Norwegian politics, the location issue played an important role. Statoil wanted Kårstø north of Stavanger. Mongstad near Bergen was an alternative, but Sotra in same area dropped out. Both Kårstø and Mongstad were thoroughly assessed both technically and financially. The ministry opted for the former. A key consideration was that the Statoil/Mobil group would bear financial responsibility for the project.[REMOVE]Fotnote: Ibid. When the Storting discussion came to a vote, 94 representatives supported a terminal at Kårstø while 54 preferred Mongstad.

Gas from the British share of the field was to go to the UK, since the licensees were not allowed to sell it to the continent. A separate pipeline was therefore laid for this output.[REMOVE]Fotnote: Development of the UK Oil and Gas Resources 2001: Appendix 14 Offshore Oil and Gas Trunk and Interfield Pipelines. Since 2007, gas exports from Statfjord have travelled through the Tampen Link, which runs via the Far North Liquids and Associated Gas System (Flags) to the UK.

A technological milestone

The 300-kilometre pipeline was laid across the Trench to a landfall on Karmøy island north of Stavanger before continuing across islands and fjords to Kårstø 20 kilometres away.

Natural gas liquids were removed at this terminal, with the dry gas then piped back across Karmøy and the Trench to the Draupner S riser platform. From there, Statpipe ran to Ekofisk and linked with the Norpipe gas pipeline to Emden in Germany and European markets. The whole giant project was costed at NOK 20 billion.

The sales agreement with continental gas buyers covering gas exports from Statfjord, Gullfaks and Heimdal was signed on 1 September 1982. Sellers Statoil, Mobil, Conoco, Shell, Esso, Saga Petroleum, Amerada Hess, Amoco and Texas Eastern secured a price characterised as “the best ever achieved”. Coordination on the Norwegian side was handled by Statoil, which led negotiations with the buyers.[REMOVE]Fotnote: Johnsen, Arve, op.cit: 130-140. The European consortium involved gas distributors in West Germany, the Netherlands, France and Belgium. It undertook to pay NOK 150 billion in 1982 value for gas from the three fields for their entire producing lives from 1986 and about 30 years ahead.

Opening the Statpipe system in September 1985 marked a milestone in Norwegian oil history. The Trench was conquered, breaching a key technological barrier – which was also important politically and economically for Norway. With Statoil’s aid, the country had secured greater direct national control over its oil industry. Much better conditions had also been created for industrialisation based on the petroleum reserves.[REMOVE]Fotnote: Ibid: 189.

Johnsen was asked on the occasion of Statoil’s 20th anniversary which decision had been the most important in its first 15 years, while he was CEO. His answer was the Storting’s 1981 decision on developing Statpipe. “The Statpipe project was special because we did something everybody else thought would be extremely difficult – laying a pipeline across the Norwegian Trench in 380 metres of water. We also laid the basis for an infrastructure of gas pipelines from the NCS, which will have enormous significance for Norway and Statoil […]”[REMOVE]Fotnote: Gjerde, Kristin Øye and Ryggvik, Helge, op.cit: 181.

arrow_backQueen’s visitDiving on Statpipearrow_forward