Pioneering production in the north

In Norse mythology, the three Norns (or Fates) shaped human densities by spinning, twining and clipping the thread of life. But it was north Norwegian lobbyists and then a unanimous Storting (parliament) who determined where Statoil’s operations team for the field named after them would be located.

Discoveries by the company in the decade before Norne was found had been relatively few and small. Supplementary resources to existing fields as well as finds such as Trestakk, Yme, Huldra and Gungne were certainly valuable, but not as impressive as Gullfaks, Oseberg and Troll. CEO Harald Norvik wrote in the annual report for 1993:

Exploration results on the NCS have been disappointing in recent years. Was a breakthrough possible in 1993? Yes, the confirmation and extension of the Norne oil discovery off Nordland county meant that Statoil could have opened a new province and reversed an unfavourable exploration trend on the NCS.[REMOVE]Fotnote: Annual report, 1993, Statoil.

Norne was actually found in 1991, but the quotation above refers to the appraisal well completed in 1993 which confirmed that the discovery was the largest on the NCS since Heidrun in 1985. Estimating the amount of oil in a reservoir is not easy, and the first assessment not infrequently proves inaccurate. Based on three wells across an area of 12 square kilometres, the field was calculated to contain about 500 million barrels – not far from today’s official figure of just under 600 million.[REMOVE]Fotnote: Statoil magazine, no 4 vol 15: 25.

John Adlam was quickly put in charge of developing Norne with the aim of reducing the time between discovery and production. The aim was to submit a plan for development and operation (PDO) to the government in 1994.[REMOVE]Fotnote: Annual report, 1993, Statoil.

Faster, cheaper and innovative

In addition to speedy, Statoil wanted a development to cost less. Norne was to be a pilot for cheaper, faster development projects (BRU), with expenditure down by 25-30 per cent. That was to be achieved through a smaller organisation, a tighter schedule, closer collaboration and fewer formalities. Collaboration with Kværner, which won the pre-engineering contract for the shipboard process, was to be conducted wearing a Norne hat, not one labelled Statoil or Kværner.[REMOVE]Fotnote: Statoil magazine, no 4, vol 16.

While the Norns decided human outcomes as they sat beneath the world ash Yggdrasil, Norne’s fate was probably not predetermined. But a water depth of almost 400 metres prescribed the choice of a production floater rather than a fixed installation.

Statoil submitted a PDO in 1994 which called for a floating production, storage and offloading (FPSO) unit combined with subsea-completed wells. The overall cost was put at NOK 9.82 billion, which required a break-even oil price of USD 7 per barrel. Measuring 250 metres long, the hull of this first NCS production ship was constructed at Far East Levingston Shipbuilding in Singapore. Stavanger’s Kværner Rosenberg yard built the ship’s turret, which was moored to the seabed while the vessel weathervaned around it. Daily production capacity was originally specified as 173 000 barrels. Along the way, however, it was decided to modify the design and increase the number of wells from 14 to 17. That boosted capacity to 220 000 barrels per day. Able to store 717 000 tonnes of crude oil, the vessel was to be owned by Statoil itself. The development utilised technology which was wholly or relatively new for the company, such as suction anchors to keep the ship on station and combustion chambers which reduced nitrogen oxide emissions from the turbines. Norne was also the first field on the NCS with an Xmas tree – the valve assembly installed on a well to control it – which was horizontal rather than vertical. This simplified maintenance and boosted opportunities for increasing output per well.[REMOVE]Fotnote: Statoil magazine, no 4, vol 16.

Who gets what?

Choosing onshore locations to support NCS operations has often been controversial in Norway, with different regions competing for the anticipated jobs and revenues from such activities. Where field operation is concerned, three sites must be chosen – the supply base for maritime transport, the heliport for personnel transport and the operations office. In addition come possible landfall sites, processing plants and export facilities for oil and gas, but these were not relevant for Norne because it was so far from land and even further from the market.

During the mid-1990s, Statoil was in the process of building up an operations organisation at Stjørdal near Trondheim for the Heidrun field in the Norwegian Sea. The company also wanted to strengthen this outfit, with Norne as one option. The alternative was Harstad much further north, where Statoil had stationed personnel since 1976 and acquired its own office complex in 1985. Local forces naturally argued that “northern Norway’s oil town” should also have an operations organisation. A view prevailed that failing to secure the Norne role would mean the end of the road for Harstad, which would be unable to secure such assignments for future fields. A Norne project group was accordingly established in the town to coordinate arguments and pursue lobbying on Harstad’s behalf.

The group, however, failed to convince the licensees.[REMOVE]Fotnote: Harstad Tidende, 20 January 1994: 10. Statoil recommended Stjørdal, largely because of the positive effects of co-location. In addition to Norne, Åsgard was under development and putting all three operations organisations under the same roof would be better and cheaper than the alternatives.

In its first recommendation on Norne, the Storting resolved in 1995 to postpone a location decision in accordance with the recommendation of the Ministry of Petroleum and Energy. This advice was to wait “until greater clarity prevails about future exploration and development activity”. How far that became very much clearer over the following year is hard to determine. On 14 June 1996, however, the Storting voted unanimously to place the Norne operations organisation in Harstad. That was in line with the ministry’s recommendation, but against the will of the licensees. The decision was justified in the following terms:

… most “objective” criteria seem to argue in favour of the Stjørdal alternative … Although there is no operational reason for more than the four operational milieus which are established today (Stavanger, Bergen, Stjørdal and Kristiansund), it is obvious on several grounds that the structure of operational milieus will not be in place until northern Norway also receives its share through the location of a fifth milieu. Politically, therefore, the question is not whether northern Norway will get its operational milieu, but rather when that should happen.[REMOVE]Fotnote: Proceedings of the Storting, 1995/96, vol 140 no 2b.

Where base locations were concerned, Statoil recommended that

Kristiansund should handle the maritime transport. If volumes were adequate, however, it would transfer the base operation to the Helgeland region of northern Norway. The helicopter base would also be in Kristiansund, with flights from the northern town of Brønnøysund if exploration activity was pursued on a continuous basis in the Vøring/Nordland region of the NCS.

These recommendations were in accord with both the ministry and the Storting.

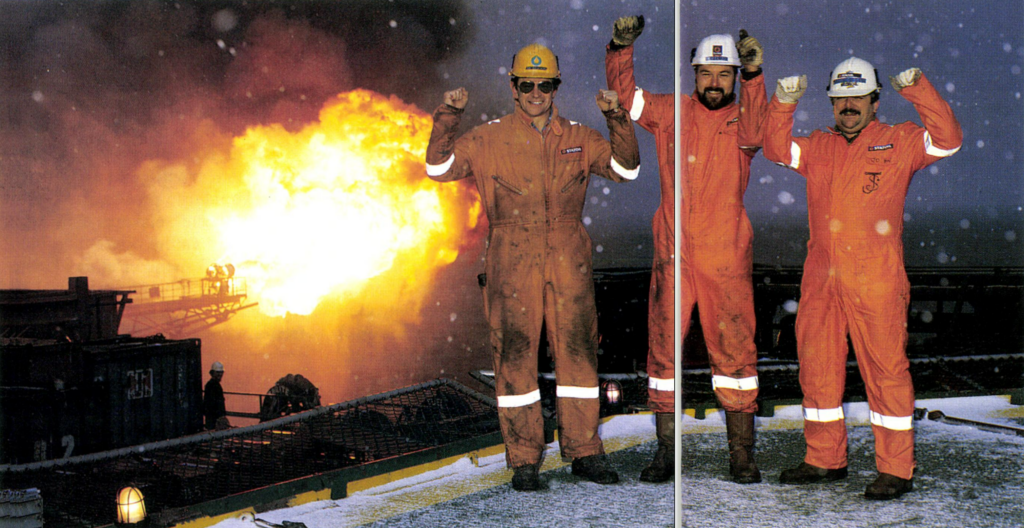

Oil on deck

What then ranked as the northernmost field on the NCS was due to start production on 1 October 1997, but a tragic helicopter accident in September caused that event to be postponed. First oil was produced by the Norne ship on 6 November and, providing crude prices held up, Statoil production vice president Kjell Helle promised that the development cost would be paid off within a year. The final price tag for the project was NOK 7.67 billion in 1994 value, and the operations organisation at start-up totalled 100 people offshore and on land.[REMOVE]Fotnote: Statoil magazine, no 3, vol 19.

Statoil originally aimed to recover 60 per cent of the oil in place, and that ambition had been achieved at the time of writing in 2022. Further reserves remain to be produced.

Norne was expected to stay on stream for 15-20 years, when the ship could hopefully be reused on another field. As with so many other NCS developments, however, its producing life has been extended. Not only has the recovery factor for the reservoir itself been increased, but the Alve, Urd, Skuld and Marulk satellites have also been tied back to the Norne ship – and more could follow.

Justified choice

Establishing an operations organisation in Harstad in addition to the existing exploration office there was important for the town. Local jobs and the security of lasting employment made this office a new power factor in the Statoil system, supplementing Stavanger, Bergen and Stavanger. Harstad became a bridgehead for exploration and production in both Norwegian and Barents Seas.

In addition to Norne since 1997, Aasta Hansteen joined the town’s operations portfolio from 2012. So has subsurface work and drilling for Snøhvit from 2007. The Johan Castberg development will also be operated from Harstad when it comes on stream, and Wisting operations will be split between Harstad and Hammerfest. [REMOVE]Fotnote: Wisting PDO part II: https://cdn.sanity.io/files/h61q9gi9/global/d099700b5ec5825bfec9e5ecadc7c72fe7e592c9.pdf?pud-del-ii-konsekvensutredning-wisting-equinor.pdf

arrow_backSleipner A GBS – lost and replacedGas from Sleipner East to Europearrow_forward