Gullfaks – the big qualifying test

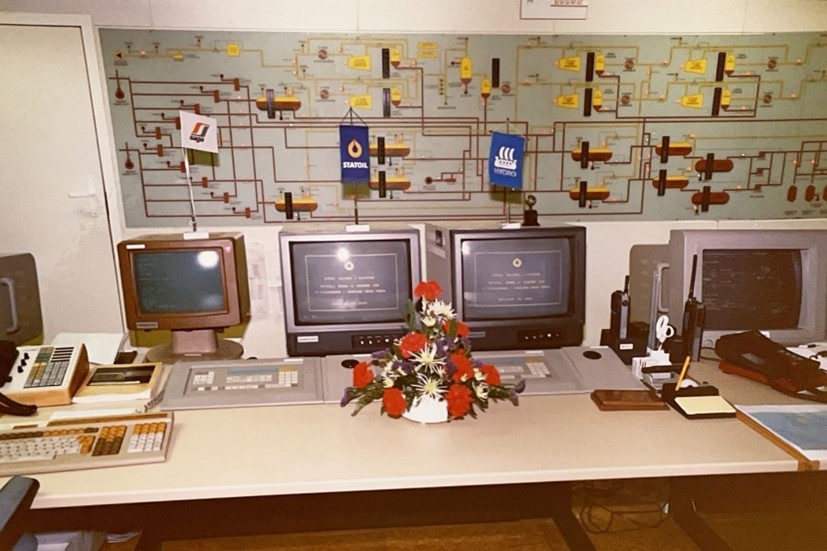

Despite its very limited experience, the company was awarded the development operatorship for Gullfaks on 9 October 1981. The Labour government had made the licence fully Norwegian, with Statoil receiving 85 per cent, Norsk Hydro nine per cent and Saga Petroleum six per cent. Nevertheless, technical assistance was required from foreign oil companies – Esso in the exploration phase and Conoco for development and production.

Difficult geology

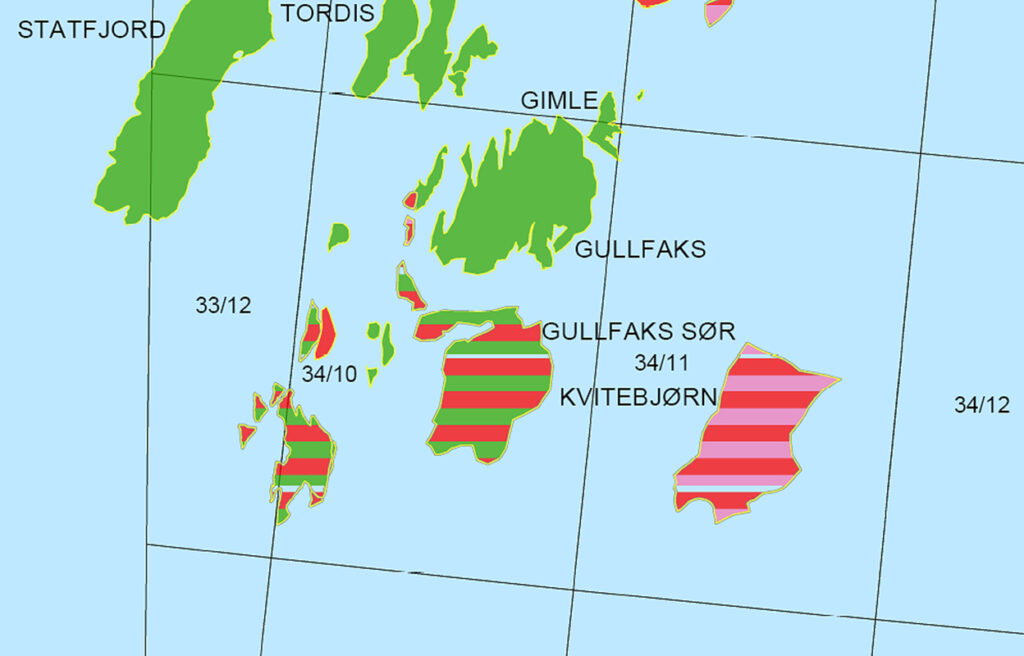

The Gullfaks reservoir was difficult to recover oil from, and significantly more complicated than “big brother” Statfjord further north. Oil and gas were spread across various types of sandstone formations.[REMOVE]Fotnote: https://factpages.npd.no/en/wellbore/pageview/exploration/all/424 On a geological map, the discovery could resemble huge waves 1 500 metres beneath the seabed, with their peaks containing the oil-filled stratum. The wildcat (first exploration well) brought up a light yellow, shimmering crude from a chalk and sandstone reservoir at a depth of 1 370 metres. Oil was also encountered in several deeper sandstone formations, as far down as 2 325 metres, but not below that.

Water depths varied from 135 metres on the western flank of the field to 220 metres on the edge of the deepwater Norwegian Trench running along Norway’s west coast. That made development more complicated, with diving to do installation work being particularly challenging at such depths.[REMOVE]Fotnote: Borchgrevink, Aage Storm, 2019, Giganten: det norske oljeeventyret: Statoil – Equinor: 110. The expertise Statoil had acquired as Mobil’s partner for the Statfjord development proved highly useful in overcoming all the challenges.[REMOVE]Fotnote: Lie, Einar, 2005, Oljerikdommer og internasjonal ekspansjon – Hydro 1977-2005: 60.

Norwegian concrete the base

The concept of offshore platforms supported on a concrete gravity base structure (GBS), already used on Frigg and Statfjord, was also applied to the Gullfaks development. Using the same template in this way saved planning time. A plan for development and operation (PDO) of the first Gullfaks phase was approved by the Storting (parliament) in 1981.

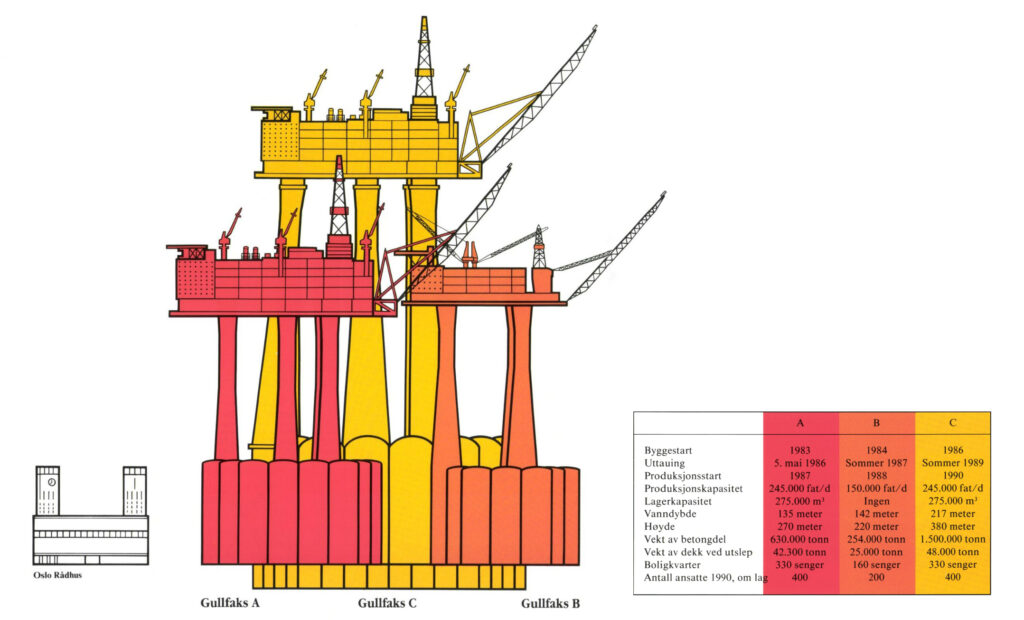

It was decided to develop the main field with three concrete giants. The A and C structures were virtually identical production platforms standing in 135 and 217 metres of water respectively. Gullfaks B was a quarters, drilling and water injection facility in 145 metres.

Statoil’s management, under CEO Arve Johnsen’s leadership, was concerned to ensure that as much of these installations as possible were supplied by Norwegian industry. Putting their topsides together from a number of modules meant they could give work to many fabricators, and no less than 80 per cent of the contracts were placed in Norway. Experience with Statfjord indicated that deadlines should not be too tight, which helped to ensure that they were met at every level.[REMOVE]Fotnote: Inderberg, Olav, e-mail, 27 June 2017.

The Gullfaks A platform came on stream on 22 December 1986, with B and C following on 29 February 1988 and 4 November 1989 respectively.

Unfortunately, the timing of this development was not as favourable as it had been for Statfjord where oil prices were concerned, given the way the latter slumped in 1986. But that was outside the company’s control.

The crude oil produced was transferred via loading buoys to shuttle tankers on the field, while the gas was piped to the processing plant at Kårstø north of Stavanger for export.[REMOVE]Fotnote: https://www.norskpetroleum.no/en/facts/field/gullfaks/

Five subsea wells

The first oil produced from Gullfaks nevertheless came not from a concrete platform but from subsea wells. Underwater technology was making rapid strides in the 1980s, and the Gullfaks licensees were early adopters of these advances on the Norwegian continental shelf (NCS) along with Elf and Shell.

Two years after the PDO had been approved, the idea of incorporating seabed wells in the concept was introduced. This was viewed as a positive step, since it permitted the recovery of reserves in satellite fields beyond the reach of platform wells.[REMOVE]Fotnote: Statoil, 28 October 1986, “Søknad om samtykke til produksjonsstart” (Ynnesdal).

Norway’s Kongsberg Våpenfabrikk (KV) company won the main contract for these subsea facilities, which were designed to eliminate the need for diver assistance during installation and operation. Humans were replaced instead by remotely operated tools (ROTs).[REMOVE]Fotnote: Inderberg, Olav, op.cit.

Technical advances give mastery

As Statoil’s first solo development, Gullfaks and its satellites incorporated many innovations.

- Statoil used specifications developed in Norway to promote Norwegian industry.

- Government requirements led to the development and adoption of quality assurance systems.

- Statoil developed project management and control systems.

- The quarters module was built with one-person cabins.

- Freefall lifeboats were developed and adopted for the first time.

- Automated drilling was utilised.

- The field had the world’s first diverless seabed production wells.[REMOVE]Fotnote: Gullfaks A prosjektet, Erindringer, 33 år etter oppstart. https://www.nb.no/items/24c9270cb2916965c47b8835c6563eb2?page=0&searchText=Gullfaks%20A%20prosjektet,%20Erindringer,%2033%20%C3%A5r%20etter%20oppstart.

All in all, the company demonstrated with the Gullfaks project that it had completed its apprenticeship and was well equipped to explore for, develop and operate petroleum fields on the NCS.

arrow_backDiverless subsea wells on GullfaksThe Statfjord money machinearrow_forward