Diverless subsea wells on Gullfaks

Underwater technology was making rapid progress in the 1980s. Statoil and Norway’s other oil companies were early adopters of these advances on the Norwegian continental shelf (NCS), along with Elf and Shell. Experience gained by Statoil – particularly with the Tommeliten field – helped to give it great faith in this new approach.

Subsea wells to improve recovery

Tying five subsea wells back to the concrete platforms on Gullfaks made it possible to reach a larger area of the reservoir, thereby increasing the field’s recovery factor and profitability.

This addition to the original plans also brought forward the start to production, which and thereby improved the economics of the project.

The concept developed was not dependent on diver support.[REMOVE]Fotnote: Inderberg, O and Knutsen, T W, 1987, “Gullfaks A Subsea Wells System Development, Completion and Production Startup” OTC 5402 MS. That eliminated a risk factor and thereby made the development safer.

Gullfaks was the first development on the NCS which eliminated the need for diving. The tragic accident involving Byford Dolphin on the Frigg field in 1983, when five divers died, was an additional argument for doing away with such work.[REMOVE]Fotnote: Gjerde, Kristin Øye and Ryggvik, Helge, 2009, On the Edge, Under Water. Offshore Diving in Norway: 231-233.

KV wins the work

Norwegian manufacturer Kongsberg Våpenfabrikk (KV) won the main contract for the underwater installations. Its subcontractors included American’s Cameron Iron Works, which provided Xmas trees and associated systems. Others supplied the control system, umbilicals and production flowlines.

In KV’s own view, its ability to deliver a diverless system was crucial to winning the contract. Nor was there any doubt that Statoil, and CEO Arve Johnsen not least, wanted the contract to go to a Norwegian company.[REMOVE]Fotnote: Olav Inderberg in an interview with Kristin Øye Gjerde and Arnfinn Nergaard.

The Gullfaks assignment also meant a great deal for the future development of KV and its subcontractors as suppliers of subsea solutions.[REMOVE]Fotnote: Tore Halvorsen, then KV’s CEO, by e-mail, 23 February 2021.

ROVs and connectors the key

Although water depths on Gullfaks lay well within reach of divers, implementing the first diverless project for subsea production carried great prestige for KV and Statoil.

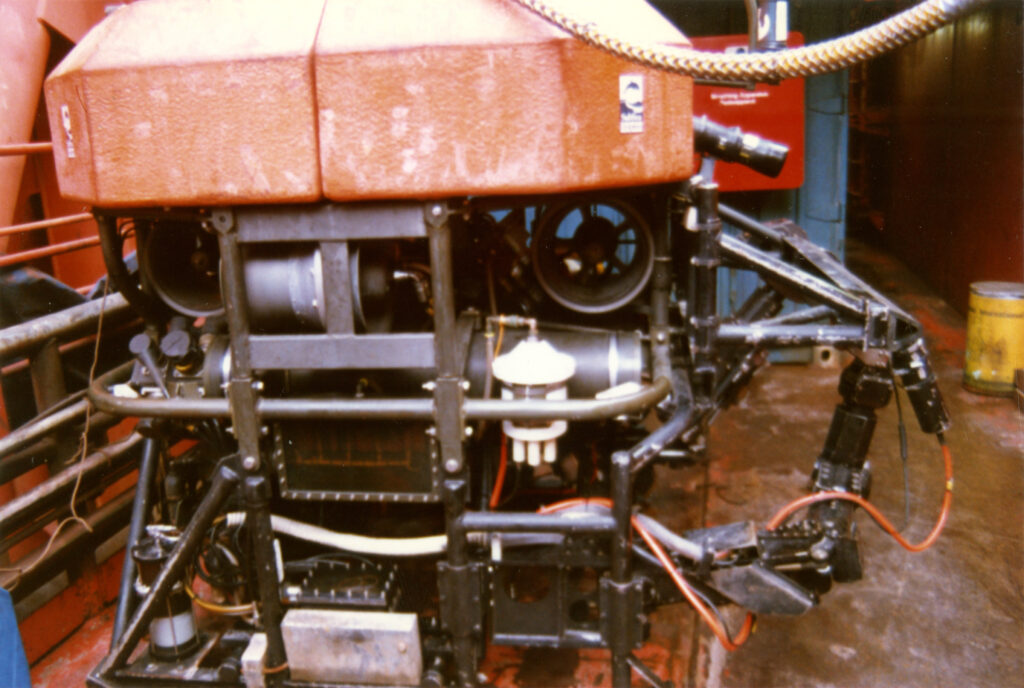

A key factor in their success was the use of remotely operated vehicles (ROVs) developed from the late 1970s, as well as remotely operated tools (ROTs).[REMOVE]Fotnote: Olav Inderberg, e-mail to Arnfinn Nergaard, 27 June 2017.

Such devices were required on Gullfaks for horizontal connection of flowlines and cables to the seabed station. The remotely controlled pull-in and connection/tie-in system was used to bring flowlines to the Xmas tree (valve assembly) on top of the well, and link these components together in an automated manner.

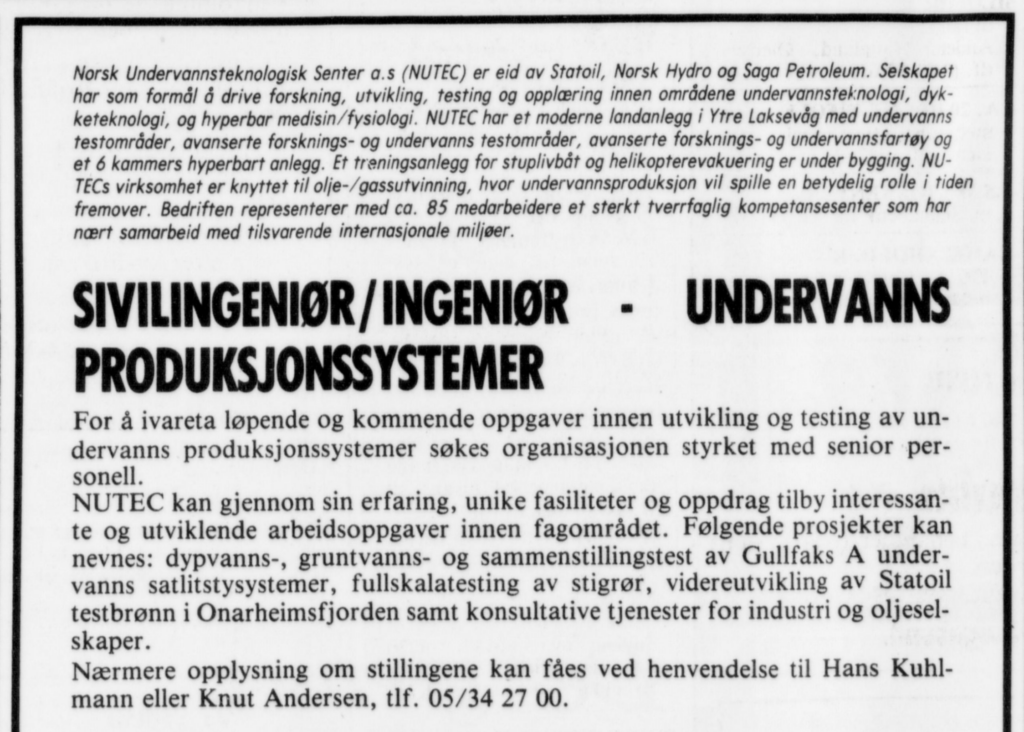

Statoil gave great emphasis to thorough testing of all equipment and connections for subsea systems on Gullfaks. This was done for deep water in the Onarheim Fjord south of Bergen and for shallow depths at the Norwegian Underwater Technology Institute in Bergen.

Odfjell Drilling secured the contract to drill and complete the subsea wells from its Deepsea Bergen rig, which also supported all the work related to connecting flowlines and umbilicals. Inocean installed the templates in July 1985.

Drilling the subsea wells began the following month. Improvements were also made to this work, which became more automated. The whole programme was completed in one year.

Early start-up

The original plan called for the Gullfaks subsea wells to come on stream in June 1987, but the first three began producing on 22 December 1986 – six months ahead of schedule.

An additional bonus for the underwater engineers was that these wells came on stream eight months before first production from the platform’s own wells.

It was particularly gratifying for Statoil that this 1986 start-up meant that it could claim NOK 400 million in tax depreciation that year rather than in 1987 as expected.[REMOVE]Fotnote: Olav Inderberg, op.cit.

The early start to production also meant that Gullfaks became the company’s first producing field as operator, just days before it took over as the operatorship on Statfjord.

A little over a month after production started, on 29 January 1987, the Ugland-owned tanker Sarita lifted the first cargo of “subsea” oil from Gullfaks A.