Gas to food – bioprotein at Tjeldbergodden

Natural gas is primarily used in Europe for space heating, cooking and generating electricity. Such stationary applications account for about 95 per cent of European consumption, with only a small proportion used as feedstock in industry.

Where industrial applications are concerned, methane in the natural gas is converted into other compounds for use in petrochemicals and producing bioproteins.

The latter are primarily employed as additives in fish and animal feed. But they can also be further processed into inputs for such sectors as food and cosmetics.[REMOVE]Fotnote: Jan Erik Karlsen, 2011, Gi gass! Energimarked mot alle odds, report 2011/108, International Research Institute of Stavanger (Iris).

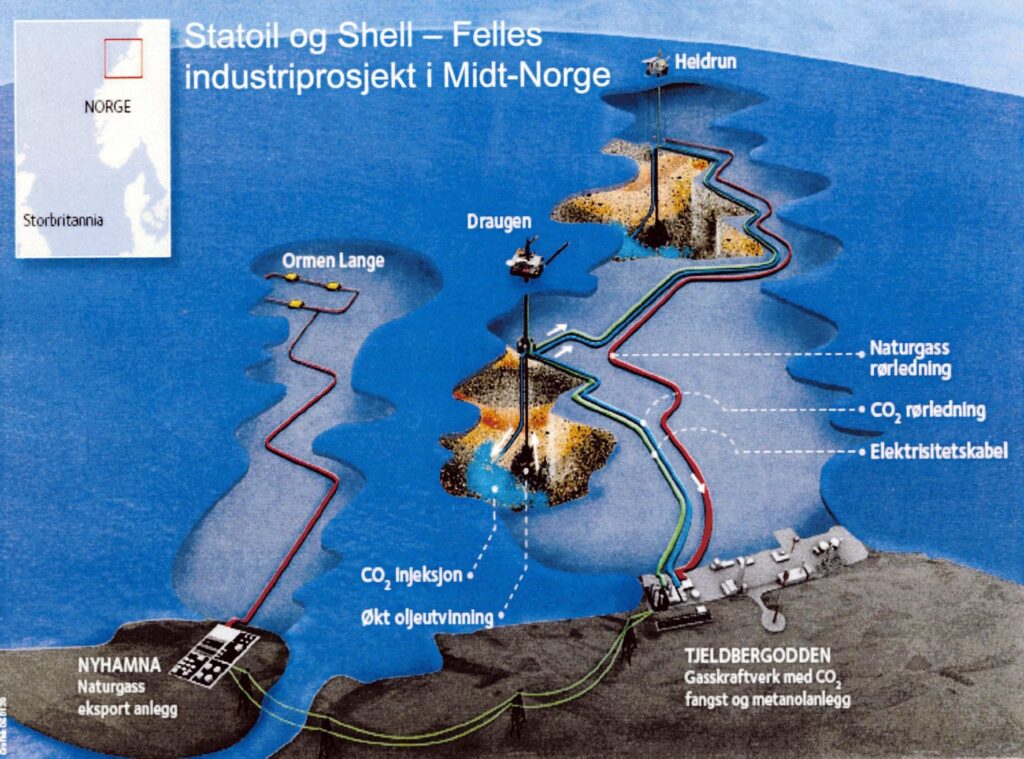

A methanol plant was constructed at Tjeldbergodden north of Trondheim in 1997, marking the first large-scale use of natural gas in Norway. With feedstock brought from the Heidrun field on the Halten Bank in the Norwegian Sea through the Haltenpipe line, this facility accounts for about 25 per cent of total European methanol output.[REMOVE]Fotnote: https://www.equinor.com/energy/onshore-facilities, accessed 3 February 2022.

However, one question was whether the natural gas could also have other applications.

Statoil had been involved in research on bioproteins since 1990 as a possible option for its big gas reserves. The Norferm company it co-owned with Nycomed, later part of DuPont, developed a technology based on cultivating micro-organisms which feed on natural gas to produce proteins.

Methylococcus capsulatus, a methanophile bacterium, grows on a mix of methane, ammonia and oxygen to create biomass. This comprises 70 per cent protein, 12 per cent carbohydrates and 10 per cent fats, and can be used in such products as fish feed.

Ready in 1999, the bioprotein plant at Tjeldbergodden was considered to be at the cutting edge of large-scale processes for converting methane into proteins. A tonne of methane from Heidrun yielded 0.7 tonnes of biomass.

After a number of start-up problems, the technology was verified and production achieved in line with the specifications. The first bag of bioprotein for use in fish feed came off the production line on 6 February 1999.

A total of 110 000 tonnes of this product was made, all utilised by Norwegian fish farmers. But the process became a cash drain for Statoil and DuPont, which jointly lost NOK 100 million a year on bioproteins. Production has halted in March 2005 because of low prices, uncertainty over EU approval of the product and challenges related to production stability.[REMOVE]Fotnote: https://www.regjeringen.no/globalassets/upload/kd/vedlegg/forskning/biotekkonferanse/iris_og_bioprotein_as.pdf; Tidens Krav, 28 October 2005.

Methanol is still produced at Tjeldbergodden, where facilities also include a gas receiving terminal and an air separation plant. Total capacity for the chemical is about 900 000 tonnes per annum.

arrow_backThe power of initiativeAcquiring a slice of Sagaarrow_forward